2. Suitable for products with similar production times (heating+disassembling molds), or for mass production of the same products.

3. It has an independent cooling station (optional with or without a cooling chamber).

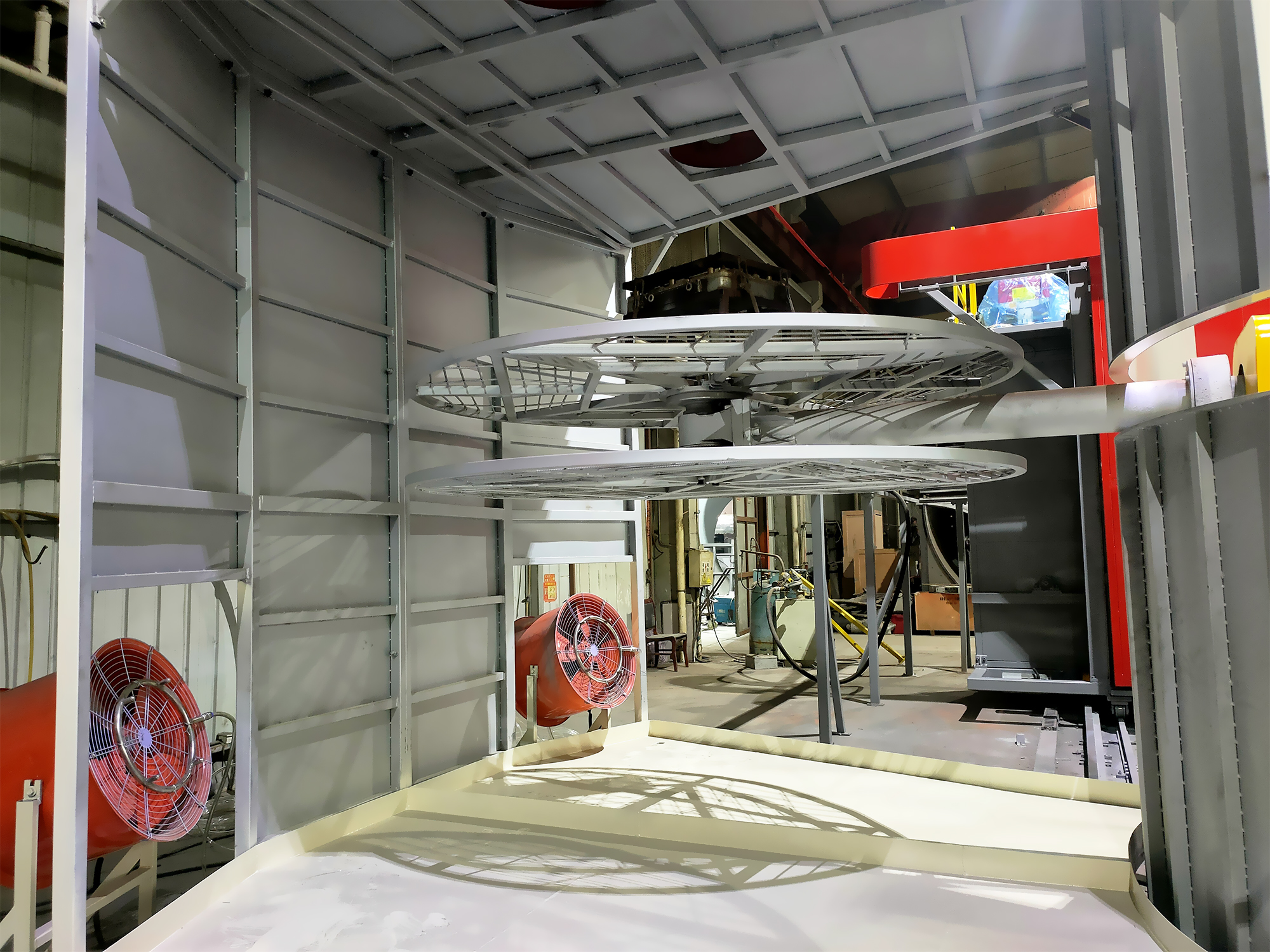

Advantages of tower rotary molding machine:

1. Heating, cooling, mold disassembly and assembly, three stations realize assembly line operation, high output.

2. It is suitable for products with close production time (heating + disassembly and assembly of molds), or mass production of the same products.

3. It has an independent cooling station (you can choose to install a cooling chamber or not).

Tower rotary machine features:

The tower rotary molding machine is recognized by customers for its continuous production and high temperature stability.

The three-arm turret rotomolding machine is equipped with a central turret, equipped with 3 moving trolleys. According to different product requirements, 4 stations (heating, cooling, mold disassembly, preparation), 5 stations (heating, pre-cooling, cooling, mold removal, preparation).

The four-arm turret rotomolding machine is equipped with a central turret, equipped with 4 moving trolleys. According to different product requirements, 5 stations can be selected (heating, cooling, mold removal, mold installation, preparation), 5 stations ( Heating, pre-cooling, cooling, mold removal, mold installation, preparation).

Mechanical part:

· The equipment assembly adopts modular design, which can be installed quickly.

· Cylindrical oven with low energy consumption and high efficiency.

. The main shaft is thicker and thicker, and the gearbox directly drives the main shaft to avoid shaking of the main shaft.

. The main shaft is equipped with an outer ф27 inner ф21 vent pipe, which can pass through a large air volume

. High quality electric slip ring, reduce failure rate

Oven:

· The temperature of the oven is abolished from the previous two-stage (high fire/low fire) heating, real-time monitoring is adopted, and the ratio regulating valve on the burner is used for fine-tuning.

. The temperature in the cylindrical oven is uniform, and the hot air is blown into the oven through the stainless steel turbofan fan under the drying tunnel, and then flows into the drying tunnel through the suction port on the top for reuse.

. The wind blows from the bottom to the top and circulates, so the accumulated material does not catch fire

. 2mm thick plate inside the duct, durable.

Combustion System:

Optional combustion machine (domestic Leah, domestic Weiru, Germany Weishaupt, American McKesson),

Fuel can choose natural gas, liquefied petroleum gas, diesel oil.

Control System:

PLC system: Delta system or Siemens system can be selected, the line is standardized, and the signal is directly connected to the control cabinet.

Reduce delay and interference caused by wireless transmission.

Heating program: each arm can set three different heating temperatures, heating time, rotation speed of the inner and outer shafts, and the size of the circulating air volume.

Cooling function: cooling time, cooling delay time, water mist (optional).

Storage function: store the production parameters of the corresponding products.

Main shaft and auxiliary shaft remote control: wireless remote control of the rotating arm, easy to disassemble and assemble the mold (optional).